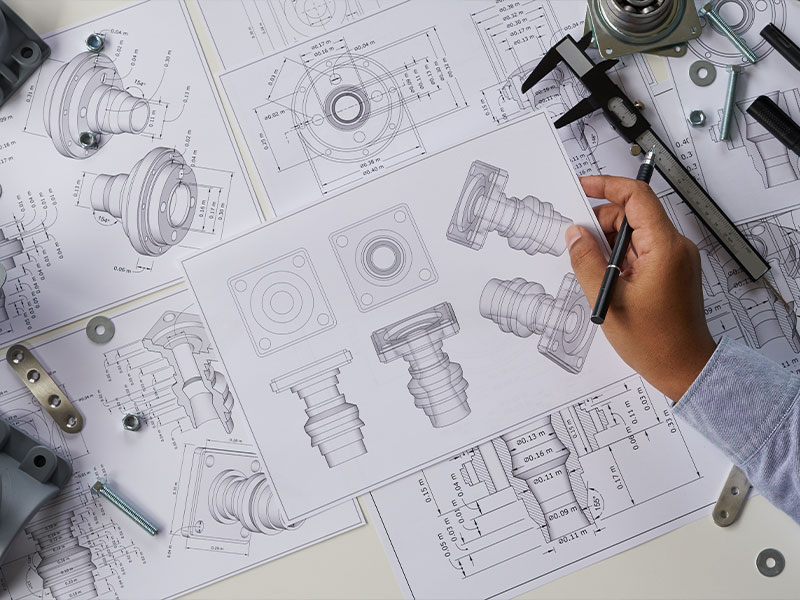

Facilities

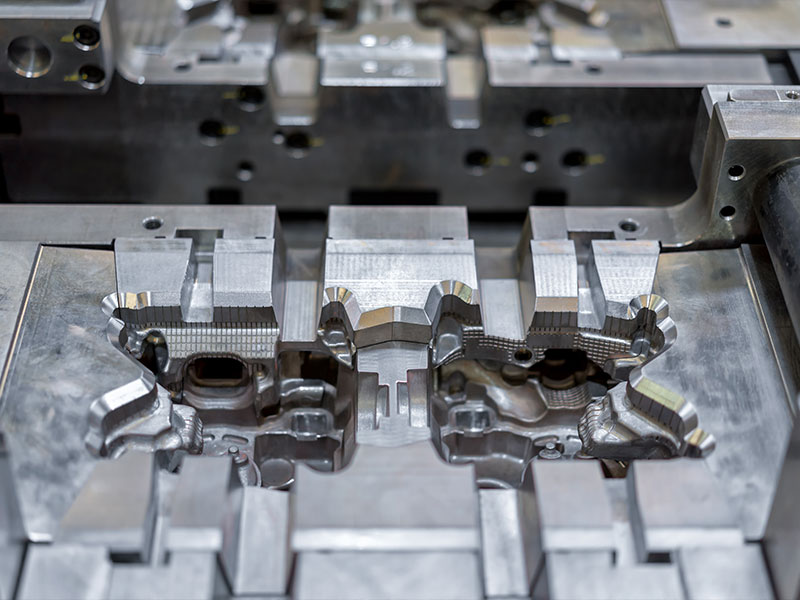

At United Brass Works, Inc., we pride ourselves on maintaining state-of-the-art facilities that support the production of high-quality valves and components for industrial fire protection, laundry, and dry cleaning applications.

Our advanced equipment and technology enable us to produce precision-engineered products that meet the demands of various industries.

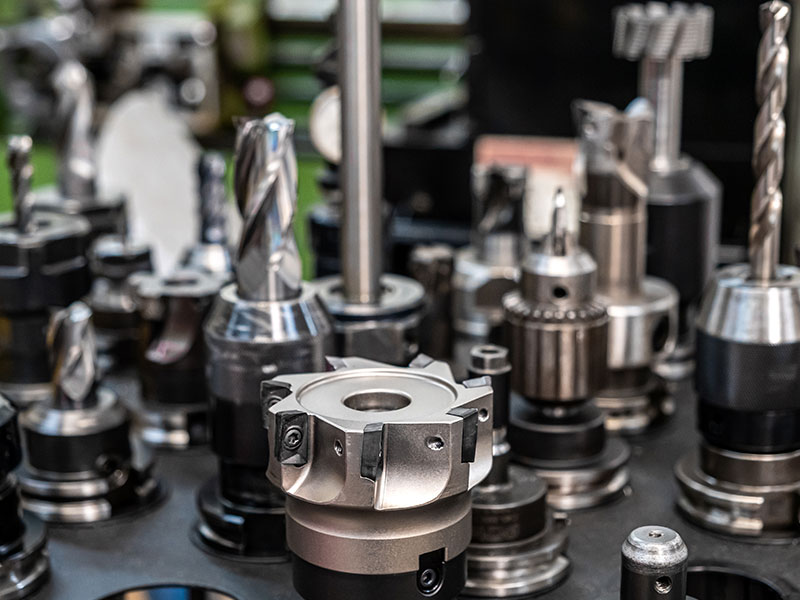

Have Questions About Machining?

At United Brass Works, we are committed to providing the highest level of machining precision and quality control. Our advanced CNC capabilities, combined with our rigorous quality assurance processes, make us a trusted partner for industries that demand excellence.

Call 800.334.3035 or contact us here to discuss your core, casting, and CNC needs with the Keystone Foundry Team.