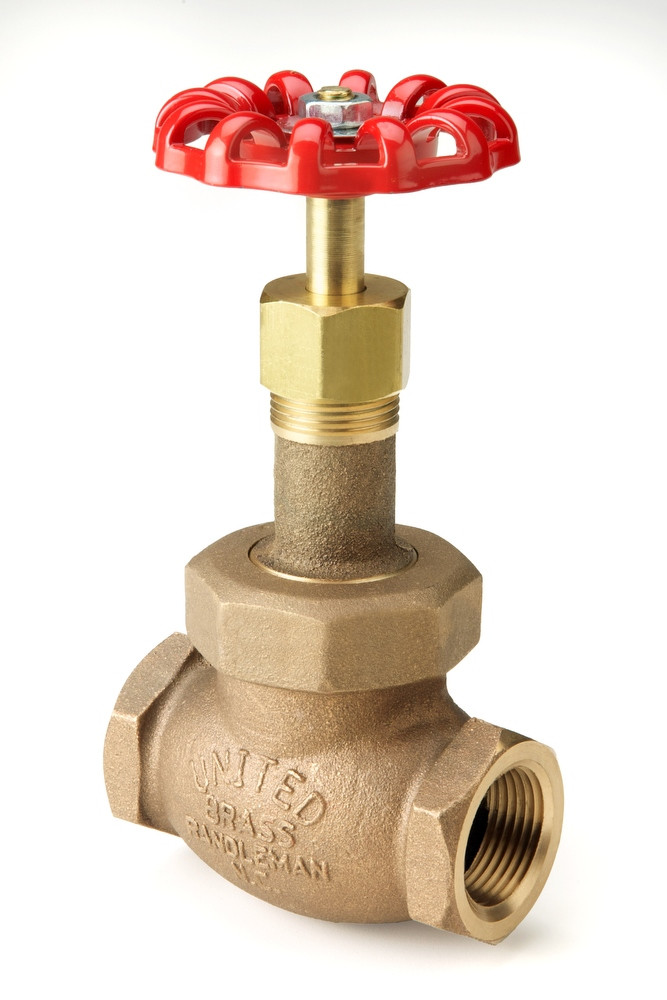

Boiler Trim Globe Valves

United Brass Works provides high-quality globe valves designed explicitly for boiler trim applications. These valves ensure precise flow control and reliable shutoff capabilities. Built for durability and accuracy, they are essential for maintaining boiler systems’ performance and safety.

Why Globe Valves Are Ideal for Boiler Trim

Boilers operate under demanding conditions, processing high-temperature steam and pressurized water. Precise flow control is critical to maintaining efficiency and preventing damage to downstream components. Globe valves excel in throttling applications, offering superior performance for regulating steam or water flow to sustain optimal boiler performance.

Our globe valves are designed to handle frequent cycling and high-temperature conditions, making them well-suited for boiler trim systems requiring frequent fluid flow adjustments. Their ability to stop flow ensures that the boiler operates safely and efficiently, reducing wear and tear on critical components. Proper flow management also helps maintain consistent system pressure, reducing the risk of costly downtime or equipment malfunctions.

How Globe Valves Work in Boiler Systems

Globe valves use a simple yet effective mechanism to control flow. The valve’s stem moves a disc or plug upward or downward, adjusting the flow of water or steam. The globe valve’s design allows operators to fine-tune the flow rate or completely shut off the fluid supply when necessary in boiler applications.

Globe valves are typically installed in feedwater lines, blowdown systems, and steam distribution systems in boiler applications. Their unidirectional design ensures proper flow direction and optimal performance, helping to maintain consistent pressure and temperature within the boiler system. Additionally, their design minimizes turbulence and energy loss, making them a reliable choice for high-performance boiler operations.

Durable Materials for Boiler Trim Applications

At United Brass Works, we manufacture globe valves using high-quality materials like brass and bronze, which are well-suited for boiler environments. These materials offer excellent resistance to corrosion, high temperatures, and pressure-related stress. For the disc, we use PTFE, which provides exceptional durability and sealing performance. The combination of these materials ensures long-term reliability, even in harsh conditions.

Advantages of Globe Valves for Boiler Trim

- Precise flow control.

- Short opening and closing times for quick adjustments.

- Long operational life due to minimal friction between sealing surfaces.

- Compatibility with high-temperature and high-pressure environments.

- Practical in applications requiring frequent cycling or adjustments.

Consider the Components

For boiler applications, the components of a globe valve—such as the seat, disc, and stem—are critical to its performance. We select the materials for these components based on the characteristics of the fluid being handled, ensuring durability and proper function in demanding conditions. High-quality components enhance sealing capabilities, prevent erosion, and contribute to the valve’s extended service life.

Globe Valve Models for Boiler Trim Applications

United Brass Works offers a wide range of globe valves to suit various boiler trim needs:

Model 125T Globe Valve

Model 125MM Globe Valve

Model 81T Globe Valve

Model 381T Globe Valve

Contact Us for High-Quality Globe Valves

Contact us today to learn more about our boiler trim globe valves or to speak with one of our valve specialists. Our team is ready to help you select the ideal valve for your boiler system requirements.