Industrial Strainers

United Brass Works offers durable and reliable industrial strainers to protect critical fluid and gas management system components. With precision engineering and premium materials, our strainers ensure efficient filtration to maintain the integrity and performance of industrial systems.

The Role of Strainers in Industrial Systems

Industrial systems often operate in demanding environments, processing high-pressure fluids and gases that can carry debris, such as rust, scale, and sediment. Over time, this debris can accumulate in pipelines, posing a serious risk to sensitive downstream equipment like pumps, flow meters, and control valves. Unfiltered contaminants can cause premature wear, valve erosion, and system inefficiencies, resulting in costly repairs and unplanned downtime.

Industrial strainers are critical preventative measures that effectively filter out solid particles and protect your system’s components. By incorporating high-quality strainers into your industrial setup, you can improve system reliability, reduce maintenance requirements, and extend the lifespan of expensive equipment. These valves are especially vital in applications where system cleanliness is essential to maintaining consistent performance and preventing operational interruptions.

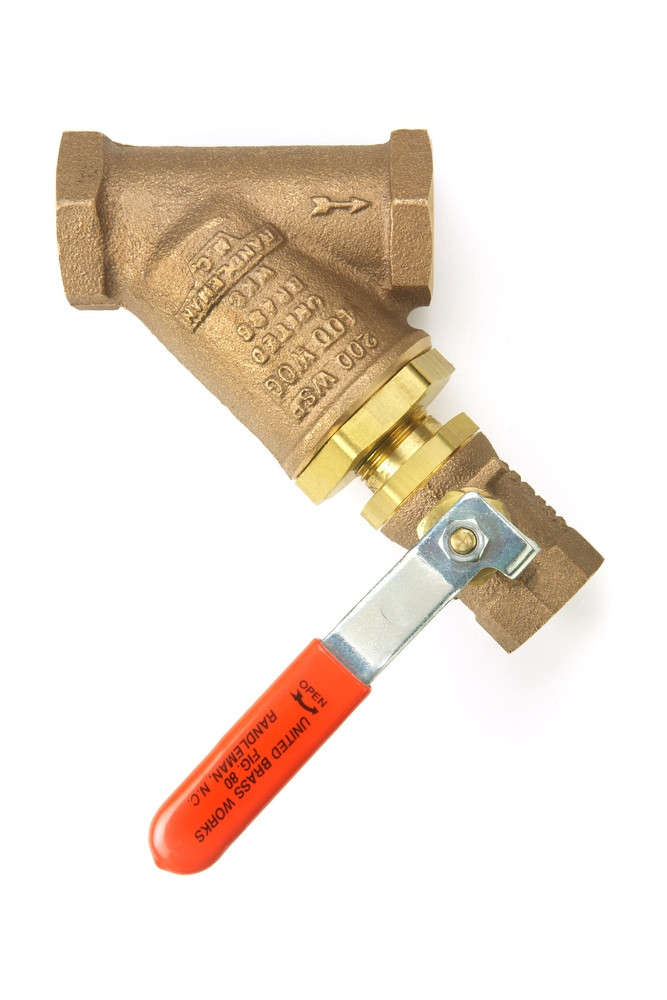

Y-Type Strainer Valves for Industrial Applications

United Brass Works specializes in Y-type strainers engineered for industrial applications requiring high performance and minimal maintenance.

- Application Versatility: Suitable for pressurized liquid or gas lines and vacuum or suction conditions.

- Convenient Cleaning: Equipped with blow-down valve options, enabling easy debris removal without stopping system flow or disassembling components.

- Flexible Installation: Designed for horizontal or vertical installation, ensuring adaptability to diverse system configurations.

Proper installation is key to optimizing strainer performance. In horizontal pipelines, the strainer pocket should align horizontally to prevent water collection, which can lead to erosion. Positioning the pocket downward for liquid systems ensures that debris is effectively collected and does not re-enter the flow during low-pressure conditions.

Built for Industrial Demands

United Brass Works constructs its industrial strainers using durable materials like brass and bronze, ensuring exceptional resistance to corrosion, wear, and challenging environmental conditions. These materials make our valves suitable for a wide range of applications, including water treatment, chemical processing, and utility systems.

Unlike manufacturers that compromise on size to cut costs, we design our strainers to be large enough to handle high flow rates while maintaining efficient filtration. This ensures optimal performance and reduces the risk of clogging or system inefficiencies. Our valves are rigorously tested to meet the demands of industrial environments, providing peace of mind and long-lasting reliability.

Applications of Industrial Strainer Valves

United Brass Works strainer valves are trusted across a variety of industries:

- Chemical Processing: Protects equipment from abrasive and corrosive particles.

- Water Treatment: Removes debris to improve water flow and reduce wear on equipment.

- Utilities: Ensures clean fluid and gas flow in power generation and distribution systems.

- Manufacturing: Maintains the performance of hydraulic and pneumatic systems.

Industrial Strainer Valve Models

Explore our selection of industrial strainer valves:

Model 200 Strainer with Steel Plug

Model 200BV Strainer With Ball Valve

Model 200WBP Strainer with Brass Plug

Model 200WSC Strainer with Solid Cap

Contact Us Today

At United Brass Works, we combine decades of expertise with precision engineering to deliver strainer valves that meet the rigorous demands of industrial systems. Contact our team today for more information, or visit any of the links above to view detailed product specifications.