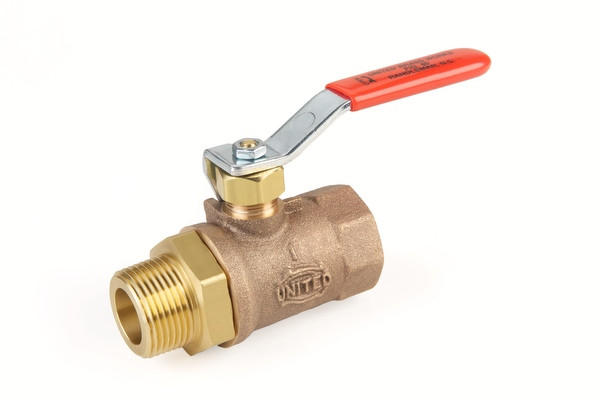

Industrial Ball Valves

United Brass Works specializes in industrial ball valves engineered for challenging conditions. Whether used in heavy manufacturing, utility systems, or complex fluid management setups, our ball valves provide unmatched reliability, precision, and ease of maintenance.

The Role of Ball Valves in Industrial Systems

Industrial systems often require valves capable of managing high volumes of fluid or gas under extreme pressures and temperatures. Ball valves are popular due to their straightforward design and dependable shutoff capabilities. They are particularly effective in applications where frequent cycling and tight sealing are necessary, such as power plants, water treatment facilities, and chemical processing plants.

Ball valves’ versatility also makes them suitable for managing diverse industrial needs, including controlling flow rates, isolating sections of a system, and reducing system downtime. With quick operation and minimal resistance to fluid flow, these valves are essential in optimizing efficiency across industrial processes. Their adaptability makes them a preferred solution for engineers designing new systems or upgrading existing equipment for improved performance.

Built to Last

United Brass Works designs its ball valves with durability in mind. Our valves resist corrosion, wear, and pressure-related damage using premium materials such as stainless steel and brass. This ensures consistent performance and reduces the need for frequent repairs or replacements.

Our valves are rigorously tested to perform under the most demanding conditions. From harsh chemical exposure to elevated temperatures, they maintain their integrity over extended periods. This durability translates to reduced operational costs and improved system uptime, making them an invaluable component in any industrial setup. The robust construction also ensures valves can handle unexpected system surges or fluctuations without compromising functionality.

Flexibility and Ease of Integration

Our ball valves are designed to integrate easily into existing systems. Whether retrofitting older equipment or incorporating into new designs, United Brass Works valves deliver reliability and versatility.

Their ease of maintenance further enhances their value, as servicing and replacing parts can be done efficiently, minimizing system downtime. This makes them ideal for industries prioritizing continuous operations and cost-effective solutions.

Specifications and Features

- Pressure handling up to 200WSP/400WOG for high-demand systems.

- Temperature tolerance up to 406°F for extreme conditions.

- Available in multiple sizes, from ¼” to 2”, to suit various applications.

- Corrosion-resistant materials for long service life in harsh environments.

- Tight sealing to minimize leaks and improve operational efficiency.

- Quick 90° operation for fast and effective flow control.

Applications of Industrial Ball Valves

United Brass Works ball valves are trusted by professionals across a variety of industries:

- Power Plants: For managing high-pressure steam and water flow.

- Water Treatment Facilities: For precise control of fluid distribution.

- Chemical Processing Plants: For handling corrosive and abrasive chemicals.

- Manufacturing: For controlling hydraulic and pneumatic systems.

Explore Our Industrial Ball Valve Lineup

Choose from our range of industrial ball valves:

Model 80 Ball Valve

Model 80MXF Ball Valve

Contact Us for High-Quality Ball Valves

At United Brass Works, we combine decades of expertise with high-quality manufacturing to deliver industrial ball valves that meet the highest standards of performance and reliability. Our commitment to innovation and precision ensures your systems operate efficiently and securely. Find out more about our industrial valves by visiting Industrial Valves or contacting our team of experts today.